-

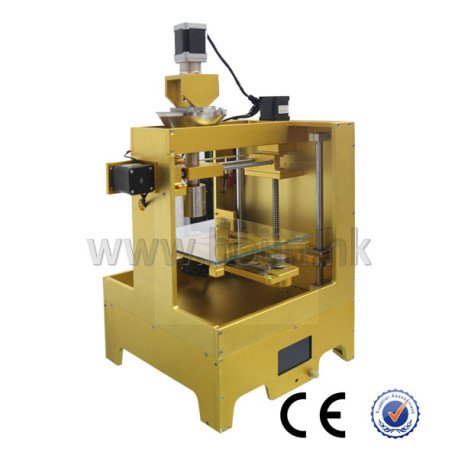

* Forming chamber size:1000*1000*750mm

* Forming chamber size:1000*1000*750mm

* Hierarchical thickness: 0.2mm(adjustable)

* Forming accuracy: ±0.2mm/100mm

* Heating Temperature of extruded head: ≦230°C(adjustable)

* Motor: stepping motor

* Dimension: 1400*1250*1350mm

-

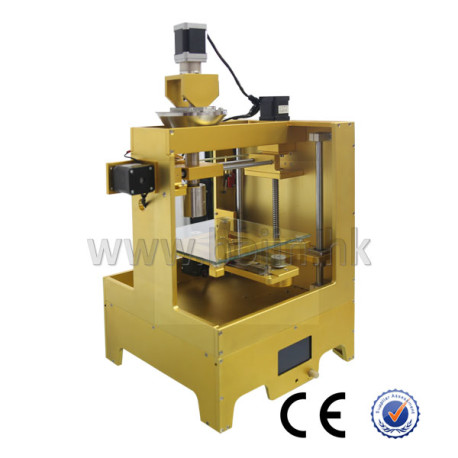

* Forming chamber size:750*600*500mm

* Forming chamber size:750*600*500mm

* Hierarchical thickness: 0.2mm(adjustable)

* Forming accuracy: ±0.2mm/100mm

* Motor: stepping motor

* Weight: 100kg

-

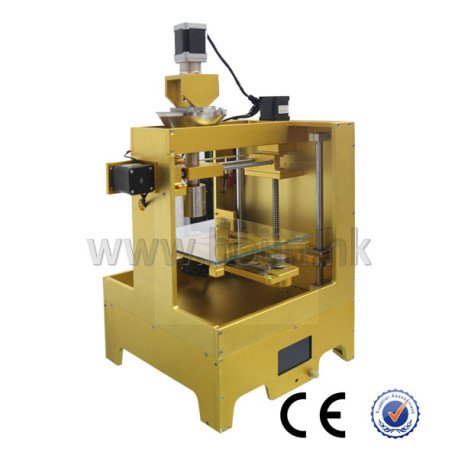

* Forming chamber size: 500*300*450mm

* Forming chamber size: 500*300*450mm

* Hierarchical thickness: 0.2mm(adjustable)

* Forming accuracy: ±0.2mm/100mm

* Dimension: 1000*700*1000mm

* Weight: 60kg

-

* Dimension:180(L)×24(W)×24(H)mm

* Dimension:180(L)×24(W)×24(H)mm

* Color:black& white,black&grey,black& blue,black&green

* Optimum temp:ABS 180-210℃,PLA 160-170℃

* Applicable materials:1.75mm PLA/ABS

* Power input: DC12V 2A 24W

-

* Technology:Stereolithography (SLA)

* Technology:Stereolithography (SLA)

* Build volume:125*125*165mm

* Min Feature Size: 300 microns/ 0.012 inches

* Layer Thickness (Axis Resolution):25, 50, 100, 200 microns

* Supports: Auto-Generated, Easily Removable

-

* Print speed:30-300mm/S, (recommend 40-100mm/S)

* Print speed:30-300mm/S, (recommend 40-100mm/S)

* Extrusion temperature:0-260℃

* Print Material:PLA

* Filament diameter:1.75mm

* Software: Cura

-

* Screen: LCD Screen

* Screen: LCD Screen

* Interface:SD card/USB

* Max Printing Object Size: 80L*80W*50H mm

* Product Dimension: 29L*29W*43H cm

-

* Screen: LCD Screen

* Screen: LCD Screen

* Interface:SD card/USB

* Max Printing Object Size: 80L*80W*50H mm

* Product Dimension: 29L*29W*43H cm

3D printer is also called 3DP, it is a kind of accumulative manufacturing technology, that is, a technology of rapid formation. It produces the three—dimensional object through printing layers of adhesive materials with special wax, powder metal or plastics on the basis of mathematical model. At present, the three—dimensional printer is used to produce the products. It is the technology by taking advantage of the methods of layer by layer printing to construct the object. The principle of 3D printer is to put data and raw materials into it, and the machine will construct the product layer by layer according to the procedures.

The biggest difference between the 3D printer and traditional one is that the former uses “ink” which is the down—to—earth raw and processed material. There are various forms of stacked thin layers, which can be used to print all kinds of media, from a wide variety of plastics to metals, ceramics, and rubber. Some printers can also combine different media to make the printed matter hard and soft respectively.

1. Some 3D printers use the way named “inkjet”, which means that using a printer nozzle to spray a layer of the very thin plastic object in the liquid state to the mold tray. This coating will be treated with the ultraviolet rays. After then, the mould tray drops down to the smallest distance, so as to make the next layer to be folded.

2. There is another technology called "fused deposition modeling”. The whole process is to fuse the plastics in the nozzle, and then go through the deposition of plastic fiber to form the thin layer.

3. For some systems, there is also a technology called “ laser sintering”, which uses powder particle as the printing media. The powder particle is sprayed on the mold tray to form a very thin powder layer, casting into the designated shape, and then to be fixed with liquid adhesive.

4. Some are using the electron flow to melt the powder particles. When encountering the complex structure including holes and cantilever, the media should be added jellies or other materials to provide support or occupy the space. The powder of this part will not be fused. At last, the gap will be shaped by washing away the support by water or airflow.

3D printing technology can be used in jewelry, footwear, industrial design, buildings and AEC, cars, aeronautics and Astronautics, dentistry, health care industry, education, geographical information system and many other fields. It is usually applied in mold manufacturing and industrial design to manufacture models or other products that can be produced directly. It means that this technology is becoming popularized. Printing food by 3D printer is the developing direction in the future.