-

* Cutting Length:20-9999mm

* Cutting Length:20-9999mm

* Max. Cutting Width:10-50mm

* Cutting Speed:90p/min

* Voltage:110/220v

* Frequency:50/60Hz

-

* Cutting Length:20-9999mm

* Cutting Length:20-9999mm

* Max. Cutting Width:105mm

* Cutting Speed:120p/min

* Voltage:110/220v

* Frequency:50/60Hz

-

* Cutting Length:20-9999mm

* Cutting Length:20-9999mm

* Max. Cutting Width:100mm

* Cutting Speed:120p/min

* Max. Blade Temp:420℃

* Voltage:110/220v

-

* Available Width: 1 ~ 7 CM;

* Available Width: 1 ~ 7 CM;

* Available Length: 1 ~ 100cm;

* Speed: 180pcs/min;

* Accuracy: ± 0.1mm;

* Power Supply: AC110V 60Hz / AC220V 50Hz 1500W;

* Measurement & Weight: 85×65×143cm 150kg…

-

* Available Width: 1 ~ 70mm

* Available Width: 1 ~ 70mm

* Available Length: 1 ~ 10000mm

* Speed: 180pcs/min

* Accuracy: ± 0.1mm

* Power Supply: AC220V 50Hz 1500W

* Measurement & Weight: 1500L×500D×600H(mm)

* Weight: 110KG/150KG

-

* Knife: Ultrasonic hot cutting

* Knife: Ultrasonic hot cutting

* Sensor: Electric eye sensor

* Available Width: 1 ~ 80mm Or as customized

* Available Length: 1 ~ 10000mm

* Speed: 200pcs/min (50mm length)

* Accuracy: ± 0.1mm

-

* Knife: Ultrasonic hot cutting

* Knife: Ultrasonic hot cutting

* Available Width: 1 ~ 80mm Or as customized

* Available Length: 1 ~ 10000mm

* Speed: 200pcs/min (50mm length)

* Accuracy: ± 0.1mm

* If you required other shape ,such as straight; swallow tail; and other shape ,It only change a cutter is OK.

-

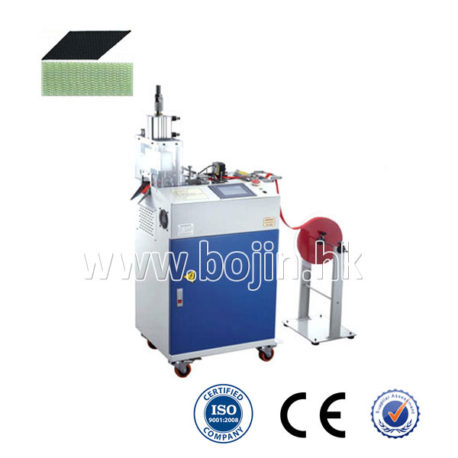

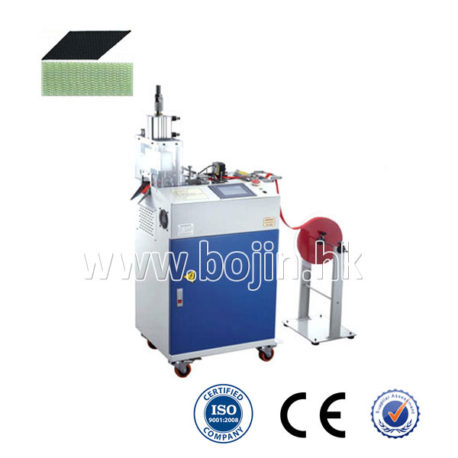

* Model:BJ-2100

* Model:BJ-2100

* Voltage: 220V

* Power: 2.3kw/2.6kw

* Cutting Length: 20-99999mm

* Max. Cutting Width: 150mm

* Cutting Speed: 120 p/min

-

* Cutting Length: 20-99999mm

* Cutting Length: 20-99999mm

* Max. Cutting Width: 100/35mm

* Cutting Speed: 120 p/min

* Sound Frequency: 20K Hz

* Recommended Pressure: 40-70Mpa

-

* Model: BJ-2400

* Model: BJ-2400

* Voltage: 220V

* Power: 2.3kw/2.6kw

* Cutting Length: 20-99999mm

* Max. Cutting Width: 100/35

-

* Shearing and folding types:

* Shearing and folding types:

* Pieces shearing

* Both edge fording

* Middle folding

* Triangle folding

* Long-short folding

* Shearable length: 15-160mm

* Shearable Width: 10-75mm

* Cutter type: Cooled shearing, hot shearing

-

* Shearing and folding types:

* Shearing and folding types:

* Pieces shearing

* Both edge fording

* Middle folding

* Long-short folding

* Shearable length: 15-160mm

* Shearable Width: 10-75mm

* Cutter type: Cooled shearing, hot shearing

Tape cutting machine is a kind of machine used to cut tape, protect film and flaky plastic material, which can be divided into automatic tape cutting machine and manual tape cutting machine according to different cutting methods.

According to the application scope of the tape cutting machine, the general tape cutting machine has the following functions: it can cut the different materials such as tape, adhesive paper and protective film. Two rolls of adhesive tape can be installed at the same time. Memory function, after power off and restarting, it still saves the original data. Circular shear function, free to set different length of cycle shear, can shear different thickness of adhesive paper. High safety performance, designed at the cutting edge.

There is a safety barrier. When the machine is blocked, the warning device works automatically. Even if the blockage is removed, the machine will not work immediately. It must press the start button before resuming work. The tape cutting machine is usually designed without rollers.

Memory function (remember 6 different lengths). Programmable 6 different lengths, presets, and cycle counting functions. Double sensor, can cut 2 rolls of tape at a time. The number of tapes that can be cut can be reduced progressively. It can accommodate any size of the inner diameter duct tape and maximum outer diameter 300 mm tape. Built-in tweezers, lubricating oil and easy to use partitions. Precise numbers control cutting length. There are many adhesive tapes can be cut, such as acetate tape, glass fiber tape, double-sided tape, polyimide film, electrical insulation material, etc.

In the domestic market, it is mainly a few domestic manufacturers competing with Korean and Japanese manufacturers. The brand price of the tape cutting machine of Japan and South Korea is much higher than the domestic brand, and the current market on the circulation of international brands are not original but mostly domestic manufacturer OEM products.